Showroom

Magnetic

Drilling And Tapping Machine have a feature for setting the tapping depth,

allowing the tapping depth to be precise and lowering the tap break occurrence

operation efficiency. This machine's design is ergonomic, with three handlebars

that alternate 360 degrees in a cycle.

An

annular Cutter is very effective to utilize. High-performance lubricants are

perfectly matched for precise drilling. They provide many of the same benefits

as mag drill annular cutters, such as faster drilling, higher hole quality, and

longer tool life.

The

beveling Machine is manufactured by using top-notch raw materials and

technology. The diameter of the pipes, the volume of pipe beveling produced,

the material of the pipes, the specifications and tolerances for bevel forms

all influence the range of pipe bevelers.

The

size, power, and characteristics of a core drill might vary based on its

intended usage. Individuals can use a tiny drill at home, whereas structures

and mines require a strong, medium-sized drill. The hollow center of the drill

allows it to carve out a sample from the drilled material.

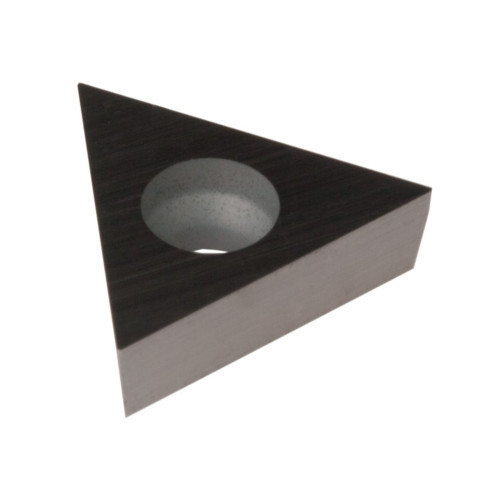

Cutting

Tools are used in machining. A stiff, hard, wedge-shaped instrument known as a

cutting tool is used to compress the work material and shear the surplus layer

of material. They are safe to handle.

End

Mill is available in a broad range of lengths, diameters, flutes, and kinds.

This mill is widely selected based on the material being cut and the needed

surface finish for the job.

HSS

Annular Core Cutter drills precise, burr-free holes to tight tolerances without

the use of pre-drilling or step drilling. BDS recommends the BDS 5200

high-performance lubricating spray for operations on a horizontal plane. This

is widely appreciated by our clients.

Milling Cutter is the most significant portion of a milling machine because this generates several sorts of surfaces such as flat, plane, and horizontal surfaces and is also used to make gears, slots, and grooves. It not only accomplish cutting but also tool changeovers automatically.